When it comes to the warehouse, nothing speaks more success like organisation does. Things can go out of control easily, from something as simple as item mixups, to the more serious damage of goods through transport and storage, and even accidents and injuries.

In other words, how seriously you consider organisation, or rather the warehouse operation, can make or break your warehouse business, resulting in loss or gain. Taking it as an essential aspect, which would logically bring about gain, you would take investment in equipment, specifically material handling in the form of pallet trolley, as a must.

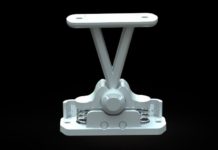

Appearing as an invention of the 19th century, meant to make the handling of heavy goods safer, the trolley, also known as the pallet truck, or pallet jack, still makes the basic component in a warehouse that not only adds to the safety, but is also affordable, versatile, and brings about a more efficient workplace.

Nowadays, there are plenty of options of pallet trolley, both simpler and more sophisticated, from the manually operated pump jacks, meant for the smaller pallet stacks, to the electric or powered pallet jacks, suitable for lifting bigger loads, as well as raised and multiple-layered pallets.

Knowing the options is one thing while knowing how to maintain them is another. Maintenance is important not only because of safety but also because it helps prolong the lifespan of the trucks which as a result allows you to cut on the repairs or replacements.

It’s good to remember check-ups are always recommended; the more often they are done, the better. This would give you a notion whether something needs to be fixed right away, with checking the oil and the wheels being a necessary routine.

Along with the oil level requiring a check-up every six months, you would also have to replace it, at least annually, whereas the wheels have to be cleaned regularly to remove the dirt that can affect the use of the truck altogether. It’s also important not to overload the truck as it puts more pressure to it, and can lead to wheel flattening or cracking.

The valve and the chain are the other parts that urge for more care, since they both can obstruct the operation of the jacks when they aren’t at their best. For instance, the valve can stop lowering the forklift, indicating the chain and the lowering valve aren’t in their correct position.