While generally considered a strong material for flooring, concrete also has its disadvantages. Most notably, it’s prone to scratches, cracks and stains which can affect its appearance and durability. This is why it’s recommended to add a layer of coating on top of the flooring.

When it comes to coatings for concrete floors, there are endless options from epoxy resin to polyurethane, acrylic and more. These coatings are typically used to shield steel reinforcement from corrosion and protect underlying concrete floors from deterioration. And in some cases, they can also add a distinctive decorative touch that elevates the whole look of the space.

If looking for a coating that offers protection and a beautiful finish at the same time, epoxy resin is the best choice. This type of treatment has many unique properties which make it suitable for a host of applications. If you want to know more about how you can use protective and decorative epoxy floor coating, here are the basics.

How Are Epoxy Floor Coatings Made?

Epoxy resin and polyamine hardener are the two separate components that make up epoxy floor coatings. Since they’re sold separately, before application, these two ingredients need to be combined.

When the resin and hardener are combined, a chemical process occurs that causes the components to cross-link as the mixture dries. The chemical reaction produces a solid, hardened plastic covering substance that adheres well to the majority of base layers.

Benefits and Uses

All types of concrete floors can be easily updated and protected with epoxy floor coatings. You can apply this type of coating in several layers to produce a long-lasting and hardy finish. And best of all, resin coatings are available in a range of colours and styles so you can get a result that perfectly matches your setting.

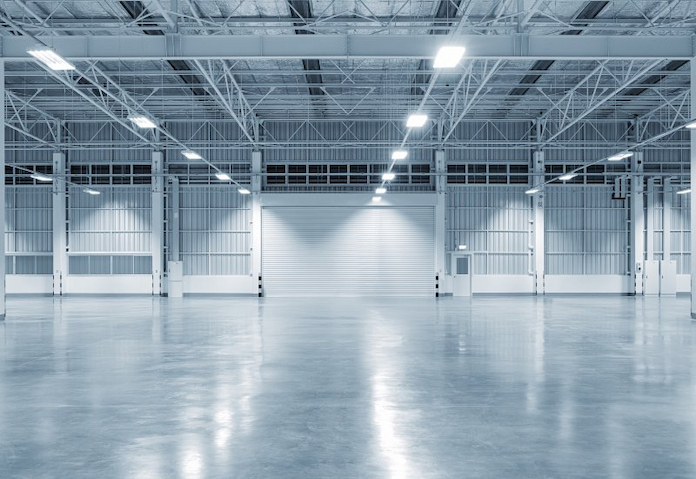

Epoxy floor coatings are renowned for their durability, impact resistance, and hardness. As a result, they are perfect for heavy-duty applications, such as industrial buildings, warehouses, logistic centres, and other locations that could experience a lot of forklift traffic because of their properties.

Another benefit of epoxy is that it can withstand chemical compounds like bleach, oils, greases, cleaners, etc. They are a well-liked option in auto repair shops due to their chemical resistance.

These types of floor coatings are also often found in residential homes. Due to their decorative look, resistance to grease and the ability to be combined with flakes to create a non-slip surface, they are often used in kitchens. And because of their toughness, they are perfect for basements and garages where fallen tools or other heavy things could damage the surface finish.

Different Types

There are three types of epoxy coatings: high solids, solvent-based, and water-based.

High Solids

A high solids coating is a one- or two-component paint that contains more solid components than a typical coat (binders, pigments, and additives) while still providing adequate coating and application qualities.

Solvent-based

Similar to water-based epoxy, solvent-based epoxy functions by adding extra ingredients that must evaporate. The strength of epoxy is only slightly affected by the use of solvent, and it is also more resistant to petroleum contamination in concrete.

Water-based

With good acid, solvent, oil, and gasoline resistance, water-based epoxy creates a surface covering or film that is resistant to water and chemicals. Of all the epoxy materials, it possesses the best impact, abrasion, and scuff resistance.

Decorative Floor Coatings

You have the options you need to fit any space with the assortment of decorative epoxy floor coating products on the market. These usually include quartz, chip blends, solids, and metallics.

Innovative coloured chip blend and resin finishes offer the appearance of terrazzo at a fraction of the cost and are much less expensive to maintain because they don’t require waxing or additional buffing.

Metallic flooring offers the natural beauty of polished or stained concrete with a vastly improved level of performance. Concrete that has been stained can fade over time in public areas, losing its colour and polish, causing ugly traffic patterns, and highlighting cracks, repairs, and porous concrete.

On the other hand, high-performance “faux stain” metallic decorative concrete coating can be applied to help conceal rather than highlight concrete substrate flaws. Thanks to the industrial-grade resin and high-performance topcoats utilised in these epoxy floor solutions, their lovely, flowing patterns apply evenly and resist wear firmly.

Lifespan

The anticipated lifespan varies depending on the floor’s intended use and environmental factors. Epoxy coatings can last for many years when applied to a floor in a home, for example. The expected life for commercial applications (such as hotel lobbies, elevator floors, and commercial manufacturing facility floors) can range from 2 to 10 years, depending on the specific circumstances.

A good maintenance and cleaning routine greatly increases the lifespan of any resinous floor coating, regardless of the application.

How to Apply It

While there are many DIY epoxy kits available, hiring a professional contractor will ensure that your project is completed on schedule, within your specified budget and with the final look you want.

Here is a rundown of the steps in case you decide to attempt applying an epoxy coating:

- Get the concrete ready – Vacuum, grind and, if needed, acid-etch the concrete;

- Apply a primer – This ensures a stronger bond between the coat and the concrete;

- Mix the two components of the coating and add any decorative accents like flakes, metallic pigments or aggregate.

- Apply the coat evenly – It’s recommended to use a special roller for this so that it doesn’t shed onto the finish.

- Apply a sealer – This improves resistance to water, chemicals, grease and impacts.