You’d be hard-pressed to find any large high-end sedan that’s not rolling on sophisticated adaptive air suspension. Luxury brands have this as standard even in mid-tier vehicles and offer it as an option on entry-level models. The system allows drivers to change the ride height and stiffness of the suspension with a simple flick of the switch, even while driving at speed. Cars can be lowered to gain a performance edge that provides better handling and response in turns, or lifted higher and the suspension absorbs road perfections with ease. The major benefit of air suspension kits though is their versatility. Individual parts offer a scope of adjustability that can’t be found in any other type of suspension.

What is Air Suspension?

Air suspension consists of airbags or bellows filled with air. These replace the standard coil or leaf springs in vehicles. Air is supplied from an internal compressor that works like any regular pump, and feeds this to an air tank. From here, the pressurised air is transferred via airlines or solenoids to each airbag. This raises the ride height. Air can also be expelled from the airbags to lower the vehicle.

The concept isn’t new and has been around as long as cars themselves. Airbags are common in heavier vehicles, like trucks and buses, and they’re also found in larger trailer and caravan setups. But it’s only a recent addition to passenger cars, especially for anyone wanting to tune the ride height either for looks or better overall performance or comfort. What’s changed is that systems today have become more reliable, are easier to fit, and some new tech has been thrown in the mix. Buyers can find bespoke airbag suspension kits for their make and model without having to do dozens of other complicated modifications.

Why You Want It

The purpose of air suspension is to achieve a smooth, comfortable ride regardless of road conditions. This is the thinking in luxury saloons with predictive suspension (with integrated cameras) which scans the road ahead and does micro-adjustments to keep the vehicle level at all times. Comfort is increased on poor-quality roads, and the level of vibration and noise seeping in the cabin is minimised. This is down to the suspension compensating for potholes, speed bumps and uneven surfaces, essentially making the car glide over the road.

The ride height though can also be lowered at any time, and this is the reason why tuners are fitting air bag suspension kits to performance cars where they help with keeping the car planted and stable at higher speeds. Ride quality when lowering the car isn’t affected, as with traditional coil and spring or coilover setups. The same cars can also be slammed down low and still be drivable. Again, not a feature possible in other suspension types.

The use of air suspension in heavier vehicles has also been adopted in Aussies’ favourite type of cars – utes. Here a load assist airbag suspension helps prevent an embarrassing sagging rear end in utes loaded to the brim. The adjustable pressure rate in airbags means the car will remain level, regardless of the weight of the load at the back. This increases safety. There’s no loss of traction or grip at the front axle and the chassis and other body components aren’t as stressed.

Utes and 4WDs can also benefit from air suspension when off-road. Each airbag can be adjusted for precise air pressure and lift individual wheels when needed. This proves advantageous in countless technical trials where stock suspension systems can struggle and get the vehicle stuck. For this reason, luxury 4WDs and SUVs have air suspension as standard equipment besides the dozens of other off-roading goodies that help in better wheel articulation when off the bitumen.

A Better Look at the Parts

• Air Bags – Airbags, air springs and bellows all refer to the main part of any air suspension kit. These are made of heavy-duty vulcanised rubber able to take air pressures of 100 psi. Airbags take the place of traditional coil springs, be it a coil-damper layout or a more common separate spring and damper setup. There are two types commonly found today. More widespread are the double-convoluted airbags, resembling two small tyres stacked one on top of the other. These have very high load ratings, a shorter stroke and a more progressive spring rate, so more commonly found sprung on front axles. Tapered and rolling sleeve airbags are more of a feature of rear axles. They are smaller in diameter and have more travel and a linear spring rate.

• Shocks – While stock springs are removed, the factory shocks can remain unchanged to the point that they suit the rebound rates of the airbags and remove the possibility of bouncing. This is a recipe for handling issues, with tyres losing grip and contact with the ground. While stiffer airbags can minimise bouncing, paired with inadequate absorbers nulls the purpose of air suspension in the first place. Most aftermarket air suspension kits include uprated (and branded) shocks that are calibrated to work with the airbags.

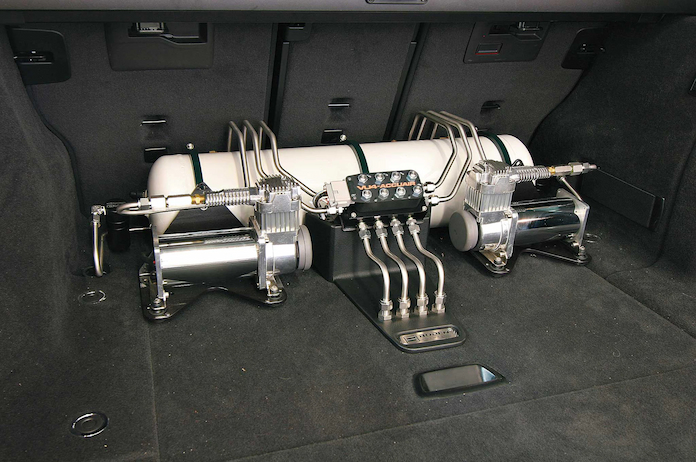

• Compressors and Air Tanks

Compressors are often 12V affairs tasked to supply the right amount of air and at the right pressure to the airbags. The air supply between the tank and the compressor can be controlled in different ways. Simpler systems have pressure switches that cut off the air when a certain air pressure is achieved. More complicated air management units digitally control how much air is delivered and when. These require minimal driver involvement, instead relying on speedy processing power and data collected from sensors to do the work for you.

Tanks store air needed to inflate airbags. This is kept at high pressure (over 150 psi) and ready to fill any airbag in a matter of seconds. Sizes can vary considerably, depending on the type of air suspension and vehicle. As can be designs, with most tuners making tanks a standout item optioned in a polished finish.

• Valves and Solenoids

Valves control the airflow from the tank to the airbags and also expel air when the vehicle is lowered. These are often mechanically operated and dash-controlled systems have a switch for each corner of the vehicle. Solenoids are electric valves often fitted between the outlets on the tank and air management controllers.

• Air Management Systems and Sensors

Digitally controlled units are the easiest to install and offer a host of advantages, such as auto levelling on uneven roads, monitoring and adjusting airbag pressure and ride height, and filling airbags with air on start-up. Newer management systems read info from height sensors mounted near each wheel and make adjustments when needed, whereas older systems rely on sensors taking pressure readings in the airbags. The latter option is not the best as weight distributed unevenly will affect airbag pressure.

• Air Lines, Fittings and Gauges

Air lines, either in reinforced plastics or braided metal designs connect the different parts. Lines can be of different diameters, in effect determining how much air can be pumped into the airbags at a given time. Manually operated kits will also have lines extending into the cabin and terminating in a pressure gauge. Each line is supplied with the appropriate fittings.