Any kind of barrier that is capable of either stopping or limiting the amount of heat getting through is considered to be a heat shield. Unlike a regular heat shields though, insulators keep the heat inside an object rather than preventing it from entering through. Heat shields come in adhesive forms too which makes them much easier to install.

A heat shield can help extend the lifespan of items since it keeps heat from deteriorating the material they’re made of. A good example for the use of heat shields is the automotive industry, more specifically the engine intake ducting. Covering this component with a heat shield can help avoid reduced oxygen density and a decrease in engine performance. But how is this possible?

How Heat Shields Work

Depending on the type of heat issue, an adhesive heat shield barrier is able to provide three different types of solution: insulation, reflection and dissipation. An adhesive heat shield mat that dissipates heat is made of special coatings and fabrics. These coatings and fabrics are extremely efficient at transferring thermal energy from one spot to another. With this type of solution, the heat passing through the shields is reduced significantly.

Adhesive heat shields that reflect heat are more commonly used than dissipators since they cause the heat

to bounce off their surface and away from an object. Insulators, as mentioned above help trap heat which is why they are used to improve performance, as well as to protect components.

Who Invented the Heat Shield?

Heat shields were invented by Robin Beck, an engineer at NASA’s Ames research centre located in California’s Silicon Valley.

What Is the Material Used as the Heat Shield?

Every type of application requires a different one. The most commonly used materials in heat shields are aluminium, stainless steel, silica, fibreglass and fibreglass yarn and basalt.

Heat Shield Applications

Military

The versatility of heat shields allows them to be used everywhere where heat is a nuisance. In military applications the use of heat shields mainly has to do with firearms. Firearms generate a lot of heat in order to exert the bullet from the nozzle which can easily cause injury to military personnel and damage accessories too. Military adhesive heat shield barriers can be useful as a strategic advantage by reducing the thermal signature of weaponized deployments such as tanks. This can help hide and secure the location of a vehicle from the enemies.

Home

On a lighter note, heat shields can also be incorporated in fireplaces and ovens or even your TV if you have placed it close to a fireplace. Radiant heat can easily damage furniture and appliances over time. By placing heat shield barriers where it’s needed, you won’t only prolong their lifespan but also keep them in better shape. This is best done with an adhesive heat shield mat since it’s easy to install and can be shaped to your liking.

Industrial

Industrial power plant machines and factories are known to produce excessive amount of heat that could damage sensitive electronic parts and also increase worker fatigue. With heat sleeves, covers, tape and shields this can be prevented by trapping the heat at its source. This lowers the amount of heat that reaches both workers and electronics. Industrial sleeves can be found used in heavy industries such as refineries, breweries, petrochemicals and fertilisers.

They are often custom made in order to provide better protection and prevent catastrophic accidents. All of the above-mentioned heat shields can also help increase the efficiency and power of industrial power plants. Heat shield curtains are also used in large industrial instrumentation control rooms and at vantage points across the whole power plant to minimise the escape of heat even further.

Vehicles

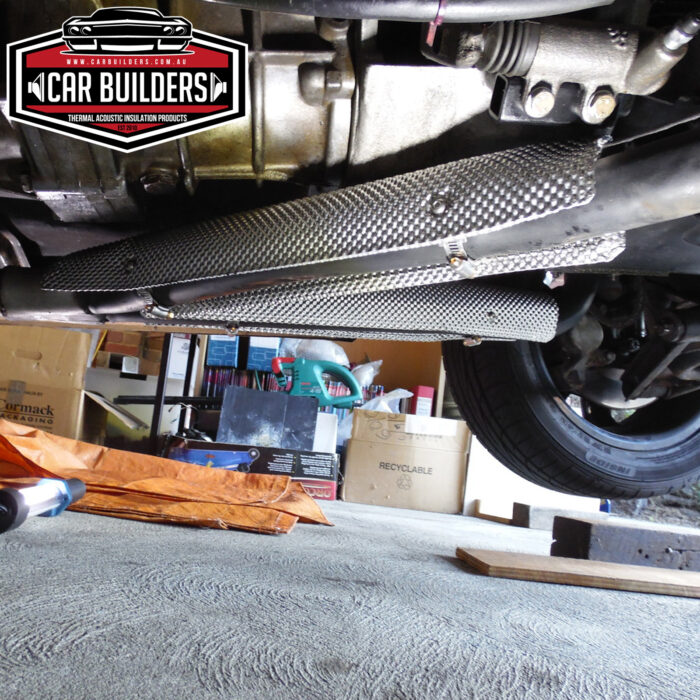

Motorcycles, cars, trucks and water vehicles such as motorboats can also be covered in heat shields, both inside and out. For cars and motorcycles the most commonly used type of heat shield is the exhaust pipe wrap. This type of adhesive heat shield barrier is made to reduce the amount of heat escaping from the exhaust system. This makes the vehicle not only more powerful and efficient, but also more responsive.

Also known as exhaust insulation, these types of heat shields can be used to provide isolation in generators, gaskets and ovens too. Heat resistant tapes are used in cars in order to improve gas mileage and prolong the lifespan of certain components such as the transmission and electrical wiring too. Thermal barriers can also be used to prevent vapour lock in fuel lines by applying them over the fuel lines which helps prevent the fuel from heating up and vaporising.