Measuring pressure can be done with a multitude of devices as it all depends on what type of pressure want to measure. When it comes to measuring the pressure of liquids, gas or steam in lines you need a manometer. Just as you need to locate faults in pipes and cables, faults can be located when measuring pressure as well. This can be done with the help of a tube, with one end of that tube connected to a gas-tight seal and the other open to the atmosphere.

All a manometer does is it calculates the difference in pressure between the open atmosphere (usually 1 atm) and the pressure inside the line. This then tells you both the pressure in the line and open atmosphere. This calculation is done with a simple equation which uses the data from the manometer such as the calculated pressure, fluids heights, and gravitational force. These three instances are measured thanks to sensors in the device itself.

How to Use Manometer to Measure Pressure

The first thing you need to do when doing this sort of procedure is to connect the local gas or water supply to the manometer. Then you need to replace one of the two arms of the manometer with a tube that has a bigger diameter. Usually, a top of the line digital pressure manometer requires connecting the supply to the aspirator. Make sure to do so to each end of the aspirator.

In case your manometer has unequal arms, you should connect it to the supply first from one side and then from the other. This way you can see where the input is. Once you take the measurements successfully, the difference in pressure will show up on the screen of the digital pressure manometer. This is where you need to know how to read the data properly to determine whether or not there are faults in the line.

How Do You Read a Manometer?

You should look at the reference level, which is marked on the tube, but in order to get accurate measurements, your device must measure the distance between the rise in liquid/ gas on one side. This is where your pressure manometer will display the density of the fluid/ gas, the reading (calculation) and pressure in N/m2. Pressure is expressed in Pascal and it will be displayed on the screen in the form of hPa, kPa or Pa.

Does a Manometer Need Calibration?

When it comes to basic manometers, they need to be calibrated since they come with a U-shaped tube. They don’t normally require calibration but when readings are off then you need to calibrate the device. When it comes to digital handheld manometers, it’s a walk in the park. With the press of a button, your device will calibrate itself (if needed) thanks to its various pressure sensors.

How to Calibrate Manometer

To calibrate a manometer you need to have a reference device in hand. This device needs to have higher accuracy than your manometer. No matter if it’s a digital or an analog device, it just needs to have better accuracy. You start by checking the measuring range of the device being tested (calibrated) to that of the reference device. You need to check if the device you are calibrating falls between the acceptable error margin of the reference device.

This is done by increasing the pressure and decreasing it through the reference device’s measuring range. Typically, you need to start at 0 and go 25%, 50%, 75%, and 100%. In case the manometer being calibrated doesn’t fall in the acceptable error margin of the reference device, it needs to have either the span or zero adjusted. You may need to use a pointer extractor for this.

To adjust the device’s zero, you’ll need to remove certain parts to get to the device’s pointer. For the span, you only need to tweak the angular adjustment slots found on the bottom of your device and you’re all good. Before you remove anything though you should mark all the percentage of the device’s measurement range.

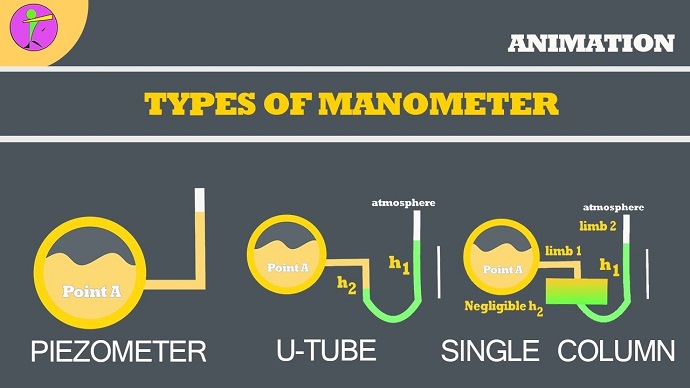

Types of Manometer Principles

U-Tube

This type of manometer method (principle) is the best way to measure pressure. Both legs of the instrument are open to atmosphere the liquid inside stays at the same level. This is good for reference and because of it, the U-Tube principle has variations. One of these variations is the Well Type principle.

Well Type

The Well Type principle includes a cross-sectional area that is bigger on the other side. This area is called ‘the well’, hence the name of the principle. As pressure is applied, the larger diameter leg moves the fluid down a bit when compared to the height of the small leg.

Inclined

If an application requires accurate measurements, then the Inclined principle is used. This principle provides low-pressure readings since it is arranged with the indicating tube inclined.